It provides engineers a whole, pre-validated platform for PROFINET IRT-compliant units, integrating {hardware}, software program, and real-time options to scale back growth time and guarantee dependable industrial community efficiency.

It’s a essential device for design engineers creating industrial Ethernet options, significantly these implementing PROFINET IRT V2.3 protocols. Industrial automation techniques demand extremely dependable, deterministic communication between units, and engineers typically face challenges in making certain each real-time efficiency and protocol compliance.

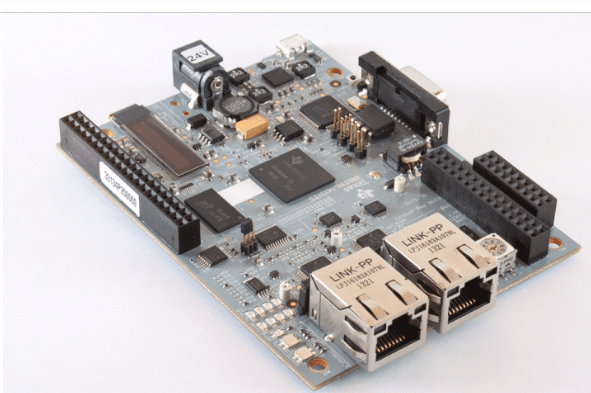

TIDEP0029 by Texas Instruments (TI) addresses these wants by providing a pre-validated, built-in resolution that mixes industrial Ethernet PHYs, a PROFINET IRT swap, a PROFINET IRT stack, and utility examples. By offering this complete platform, the reference design considerably reduces growth time, lowers threat, and accelerates time-to-market, making it an indispensable useful resource for engineers aiming to create strong industrial Ethernet units.

Designed for flexibility, the design helps a number of analysis modules, together with the TMDSICE3359 and TMDXICE110, enabling engineers to pick out the {hardware} that most closely fits their utility necessities. The design adheres to PROFINET conformance lessons A, B, and C, making certain compatibility with a variety of business community configurations. Important real-time options corresponding to a 250-μs cycle time and one-step-time synchronization (PTCP) are inbuilt, facilitating exact timing and coordination throughout units. Moreover, the inclusion of eight client and supplier protocol machines ensures environment friendly information trade, whereas the Media Redundancy Protocol (MRP) supplies community reliability and continuity, even in case of failures, which is important in industrial environments the place downtime may be pricey.

It has integration of ordinary communication stacks, together with the Molex PROFINET stack and the Interniche SNMP stack. This integration permits engineers to concentrate on application-specific growth fairly than low-level protocol implementation. Moreover, the design is accompanied by complete documentation, together with detailed schematics, PCB layouts, and a whole invoice of supplies. These assets allow speedy customization and validation of the design, permitting engineers to adapt the reference design for particular industrial purposes with confidence.

It serves as a whole, dependable, and scalable basis for creating PROFINET IRT-compliant units. By offering validated {hardware} and software program parts, intensive documentation, and real-time efficiency capabilities, it empowers engineers to develop high-performance industrial Ethernet techniques effectively. Leveraging this reference design ensures compliance with business requirements, minimizes growth dangers, and accelerates the journey from idea to market-ready resolution, making it a significant asset for industrial automation tasks.

TI has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) format, and extra. The corporate’s web site has extra information concerning the reference design. To learn extra about this reference design, click here.